Services

Turbine and Generator Services

When it comes to best-in-class lifetime management for your rotating main equipment, it’s our job to offer the best technical – and most economical – solution for each specific customer environment.

One-stop shop

A full range of capabilities from site service, engineering and workshops to modernisations at your use

Efficiency enhancements

Customised OEM-independent services based on actual equipment condition and operational priorities save both time and money

Peace of mind

Our skilled experts, optimised maintenance intervals and higher level of plant availability guarantee peace of mind

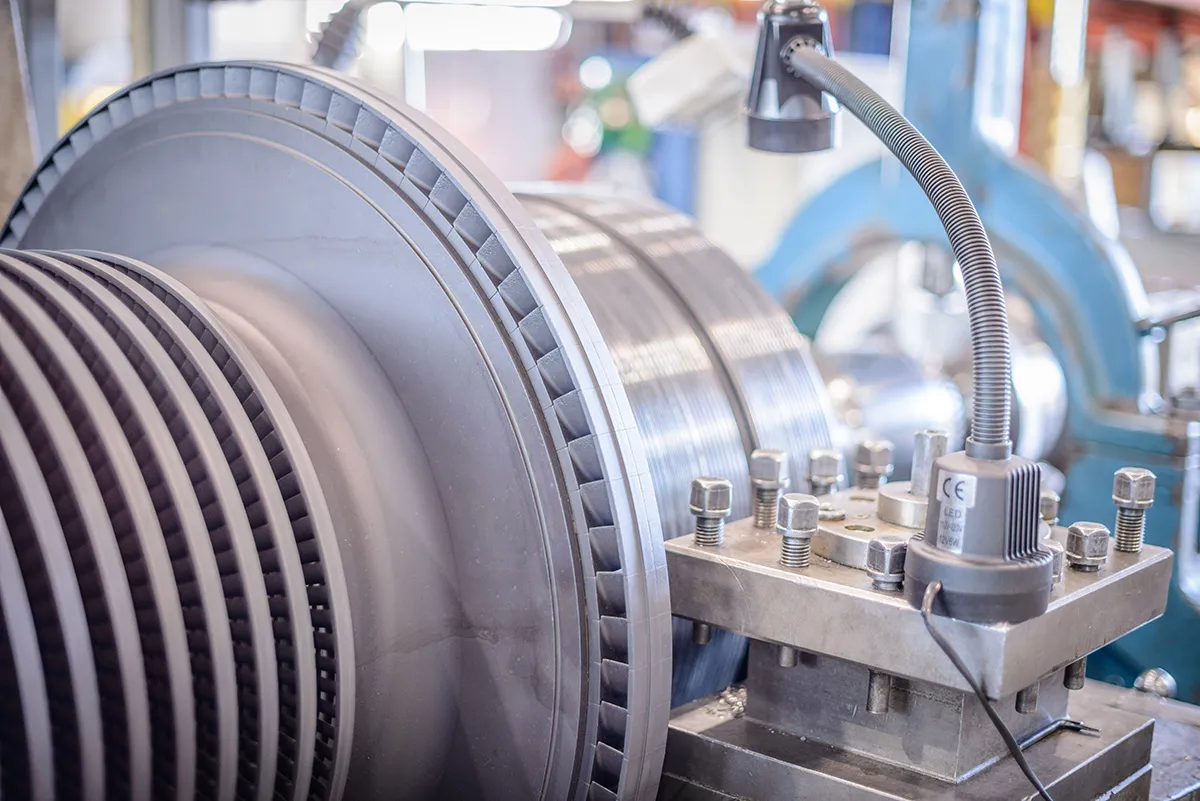

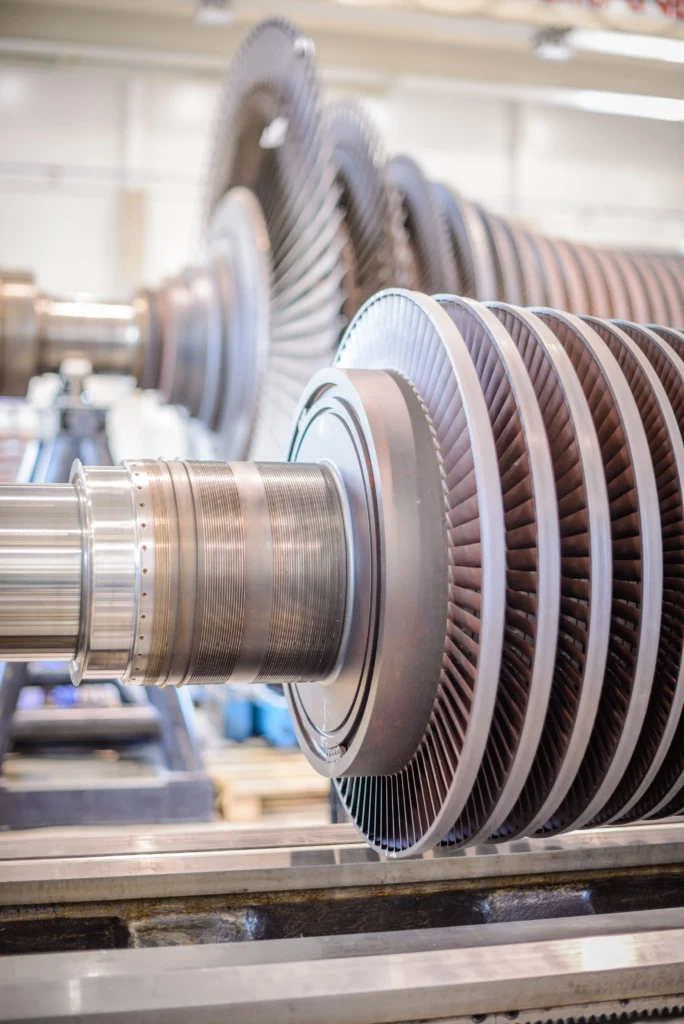

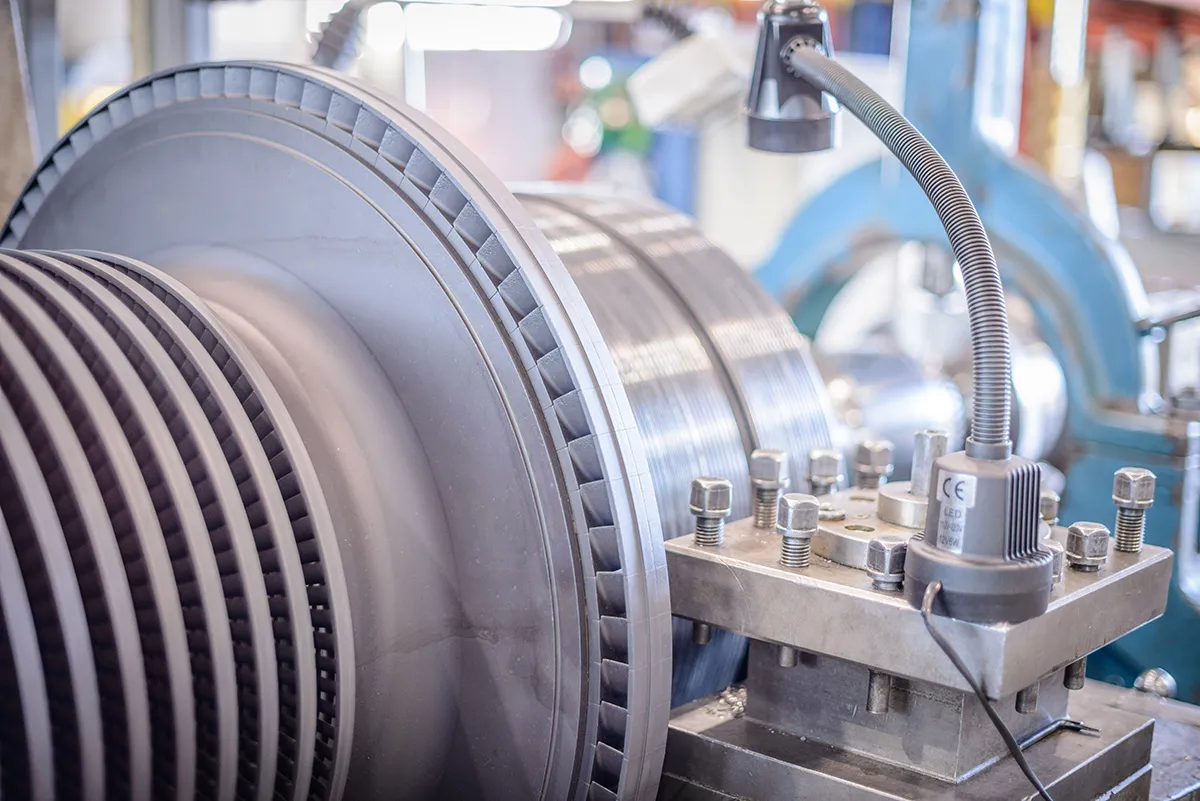

Full range of services for turbines and generators

Operating environment for power producers is changing rapidly: renewable energy solutions are on the rise, production facilities are aging, and production optimisation needs are driving plant owners to use rotating main equipment outside of the designed values and go from steady state operation to cyclical operation. Greater focus on cost efficiency and diminishing expertise on turbines and generators within customers’ own staff increase the challenge even further. In this environment, a partner that provides holistic support in improving the performance of customer assets is invaluable.

Extensive experience in providing turbine and generator services

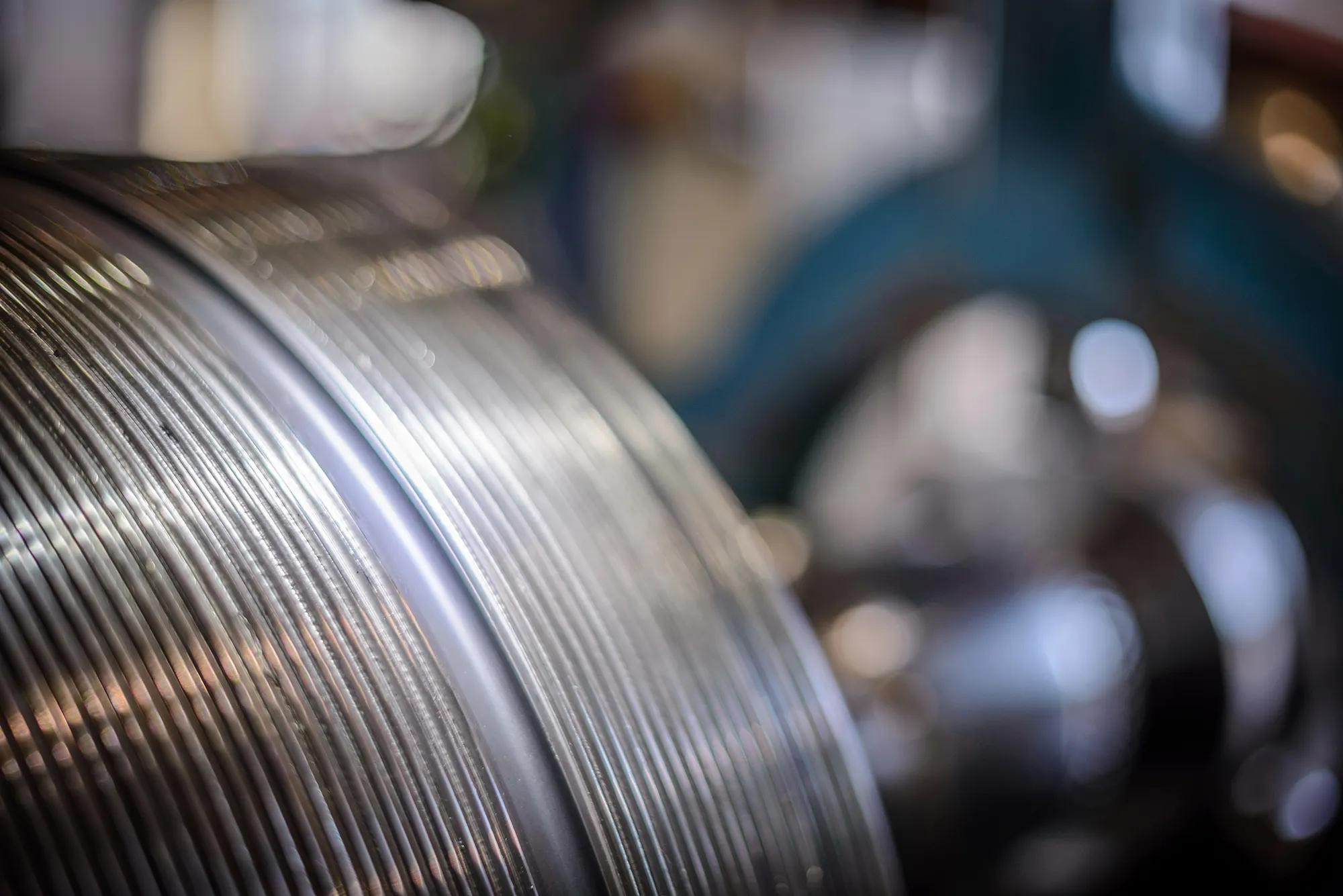

With more than 30 years of experience in providing turbine and generator services, we are uniquely positioned to support thermal power producers in their turbine generator maintenance management. As an OEM-independent service provider, we always offer the best technical – and most economical – solutions for each customer’s environment and needs. Our offering includes such services as turbine plant relocation, generator stator and rotor rewinding, turbine rotor reblading, turbine casing erosion and corrosion repair, and turbine automation as well as control and protection systems modernisation. Our services are typically provided during standard minor and major overhauls, which means delivering against tight deadlines; this requires agility, first-rate project management and an extensive and specialised partner network.

More than just keeping your main rotating equipment in operation

As an experienced and reliable service partner, our support extends beyond keeping your main rotating equipment in operation. We help you adapt to the turbulent energy production environment and improve your plant’s performance by ensuring efficient use of resources, optimising the service life of turbine generators, securing their availability and optimising risks to an acceptable level. This in turn drives your business growth.

Explore our services for turbines and generators

Turbine maintenance and repair

Our turbine plant expertise covers services including small inspections, large overhauls, upgrades and modernisations. As an OEM-independent service provider, our knowledge of the world of steam and gas turbines is comprehensive.

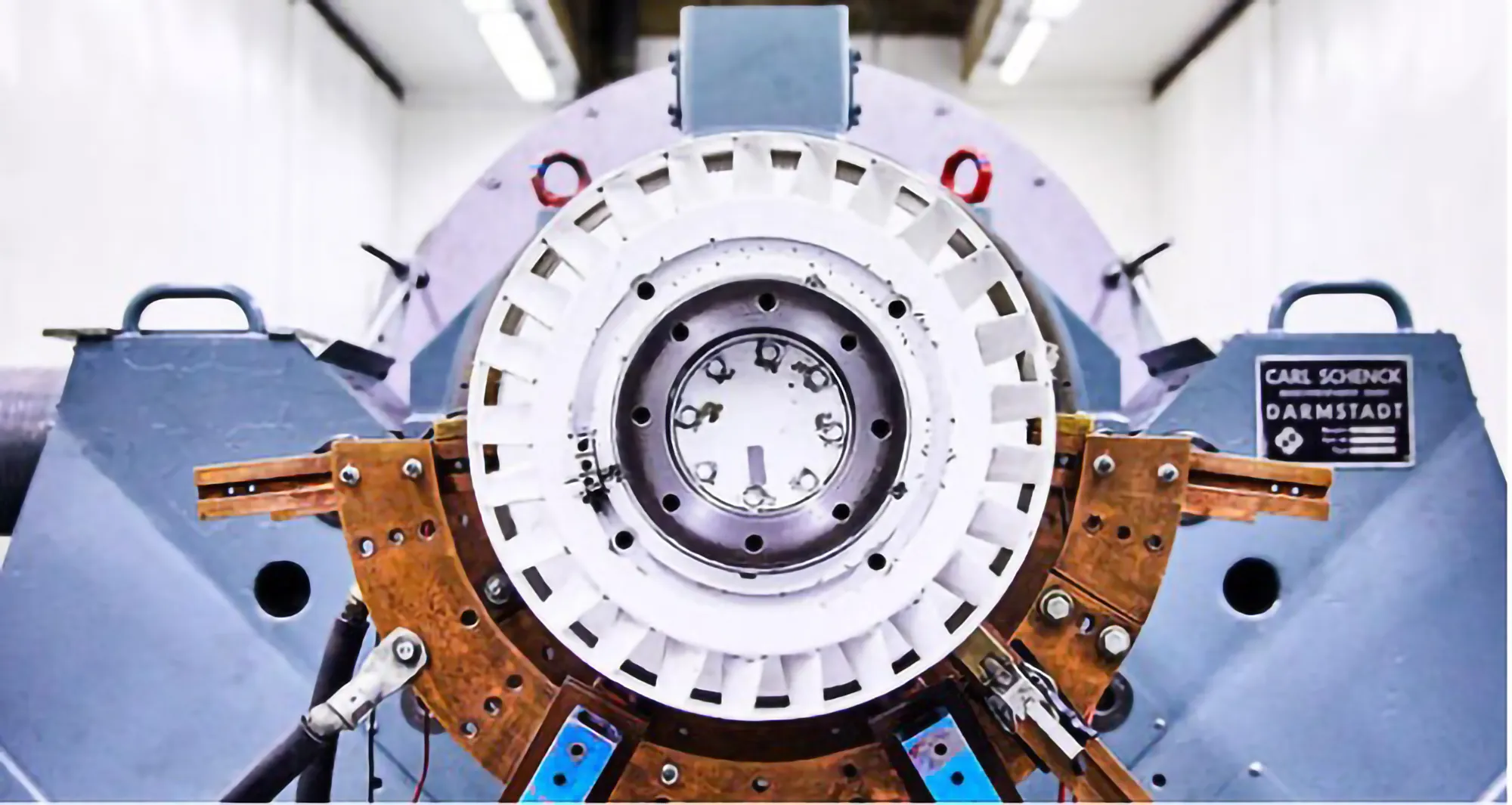

Generator maintenance and repair

Our generator expertise is based on offering a full range of maintenance services from standard overhauls to upgrades, modernisations and delivering new components tailored to specific needs. With help from a knowledgeable partner, you can get the most from your high-value turbomachinery.

Turbine and generator control and protection systems

An essential part of Elcoline’s turbine and generator expertise is providing services and modernisations for monitoring, control, and protection systems. These systems guarantee the performance of your rotating main equipment and are in a key role when looking for more visibility, reliability, and safety

Long-term service agreements

Turbines and generators are special equipment whose maintenance require special competence. Read more about our long-term service agreements.

Contact our specialist for more information

Head of Sales & Projects

Thomas Vesterlund

thomas.vesterlund@elcoline.com

+46 70 6598902

Explore our customer reference stories

-

Södra Cell

Elcoline Turbine and Generator Services – TGS to rewinded two generator rotors and stators of a fleet of radial steam turbines for a customer in Sweden

-

BIR Avfallsenergi AS, Norway

Managing the life cycle of high-value and high-risk turbomachinery, case BIR Avfallsenergi

-

Neve, Finland

Modernisation of steam turbine automation brought flexibility to production – Case Neve, Finland